- Our Business

- IoT

- Overview

Overview

Harness the OT data needed to improve

industrial operations at the edge and across the enterprise.

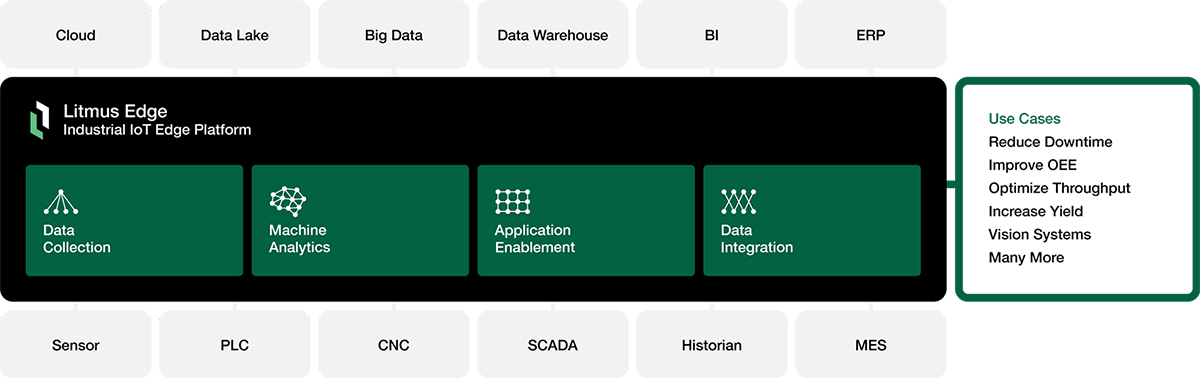

Litmus Edge is the Industrial IoT platform purpose-built for Industry 4.0. With instant connectivity to

hundreds of OT assets, Litmus Edge makes it easy to harness the OT data needed to power insights

at the edge and across the enterprise. From data collection and machine analytics to application enablement

and data integration, Litmus is a complete IIoT platform that is rapid-to-deploy and easy-to-use,

offering everything you need to improve operations at scale.

-

- One Platform

- Everything you need for Industrial IoT including complete OT connectivity, machine analytics, secure data integration and application enablement.

-

- Device Connectivity

- Rapidly collect and normalize data from any modern or legacy OT asset into one standard format ready for use by edge and enterprise applications.

-

- Machine Analytics

- Access pre-built or custom data visualizations, KPI dashboards, and analytics at the edge to improve OEE, reduce downtime and optimize throughput.

-

- Application Enablement

- Host applications in a public or private marketplace, rapidly deploy them using containers at the edge, and run them with complete OT data.

-

- Data Integration

- Easily and securely integrate data between OT and IT using pre-built integrations to dozens of cloud and enterprise systems.

-

- Flexible Deployments

- Deploy easily into any OT or IT infrastructure – run on any edge gateway, virtual machine or container (Docker, Kubernetes, etc).

One Industrial IoT Platform – Many Capabilities

-

Collect Machine Data

With 250+ pre-built drivers, Litmus can connect to any machine

or industrial system out-of-the-box, then structure it into

a common format ready for use by edge and enterprise applications.- Any asset – PLC, DCS, SCADA, Historian, ERP

- Pre-loaded drivers, no programming required

- Normalize hundreds of custom data points

-

Analyze Data

Monitor and analyze machine data with ready analytics and

custom data visualizations for condition based monitoring,

predictive maintenance, OEE optimization and more.- Analyze data at the edge for instant value

- Pre-built analytics dramatically reduce setup time

- Utilize Grafana open source-based dashboards

-

Share Data with Enterprise Systems

Immediately feed ready-to-use machine data to any cloud or

enterprise application to achieve a complete edge-to-cloud

data picture for OT, IT and Data teams.- Normalized data ready for use by any application

- Simple drag-and-drop editor to send data anywhere

- Pre-built connectors to integrate to cloud systems

-

Run Applications

Host and access public or private applications in a centralized

repository with the ability to rapidly and securely deploy

and run applications at the edge.- Access a default set of 45+ pre-loaded applications

- Deploy container-based applications with one-click

- Zero-touch provisioning and mass management

-

Manage Deployments

Achieve a single point of control to view and manage a complete

picture of edge devices, data, applications and deployments at

scale with Litmus Edge Manager.- Visualize data from all devices and factories

- Bring in and manage any digital twin or data model

- Create an ideal configuration template to use on any line or site

One Industrial IoT Platform – Many Capabilities

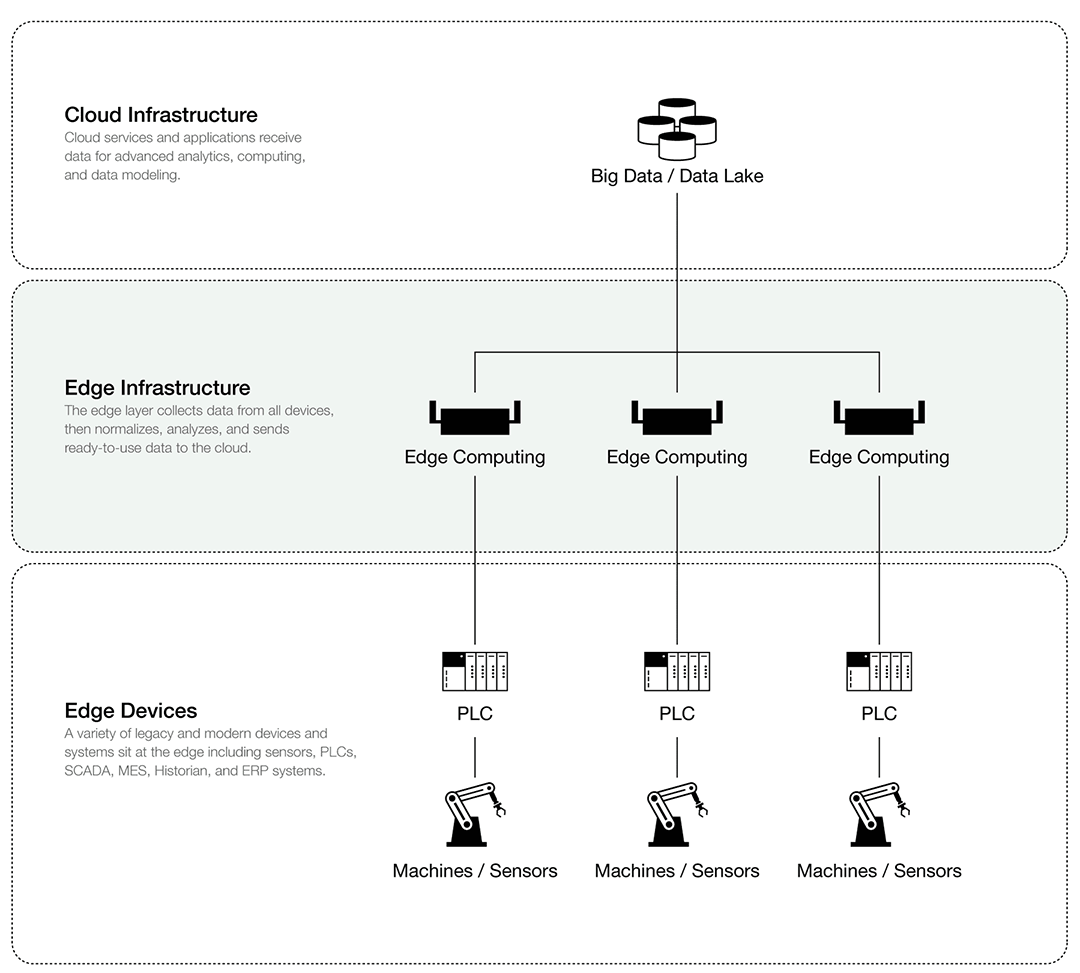

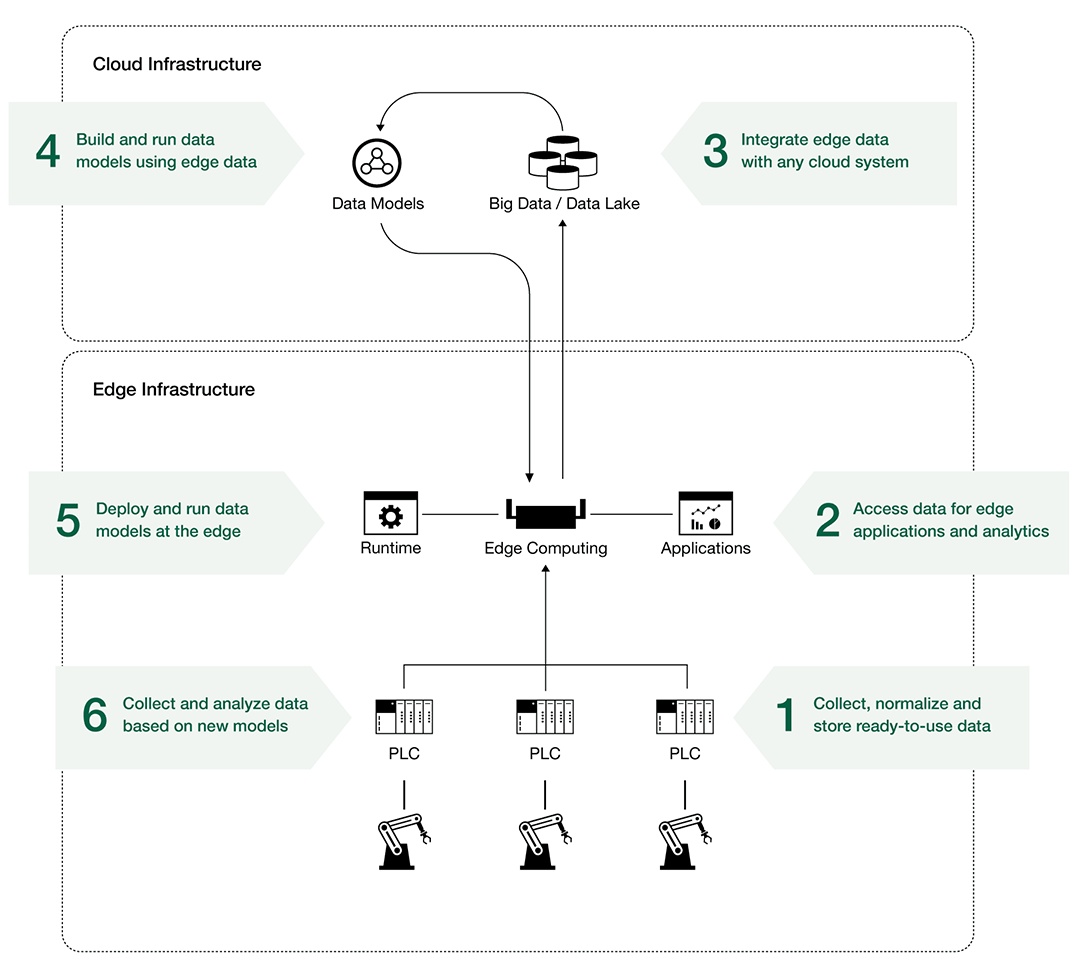

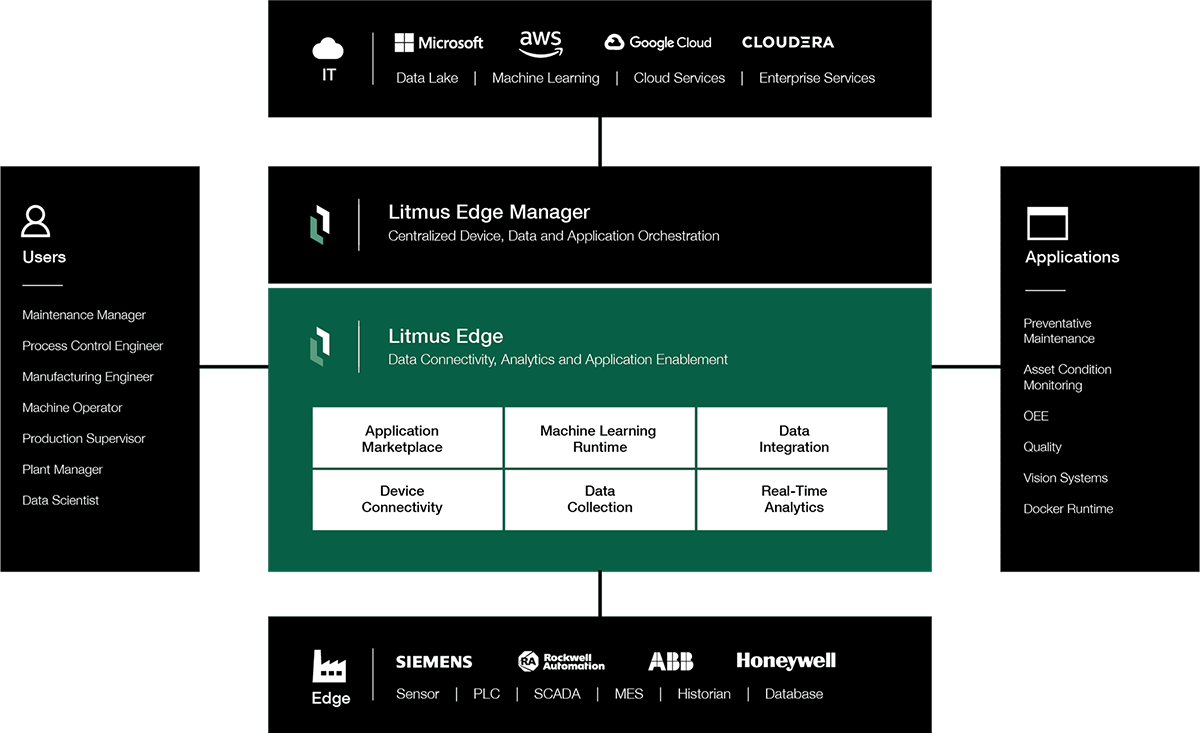

How Edge-to-Enterprise Industrial IoT Works

Industrial IoT requires seamless and secure edge-to-enterprise data flow.

With Litmus, IT and OT teams work together to connect all machines and start collecting data.

Data is stored and

analyzed at the edge, where OT teams can use

it to increase uptime and efficiency,

and IT can define what data to send to cloud and enterprise systems. There, data teams perform deep analysis,

build models and deploy them back at the edge to

improve operations over time.

-

- OT Teams

- OT teams use data collected by Litmus Edge to run analytics that help them understand machine behavior and reasons for downtime. They make data-driven decisions and run applications to improve operations.

-

- IT Teams

- IT teams manage how Litmus Edge is deployed - at the edge, in the data center or in the cloud. They make sure all edge devices, data and applications are running as planned with central control and security.

-

- Data Teams

- Data teams access normalized manufacturing data from Litmus Edge. They run analytics to understand what is happening at the edge, then build and deploy machine learning models to improve operations.

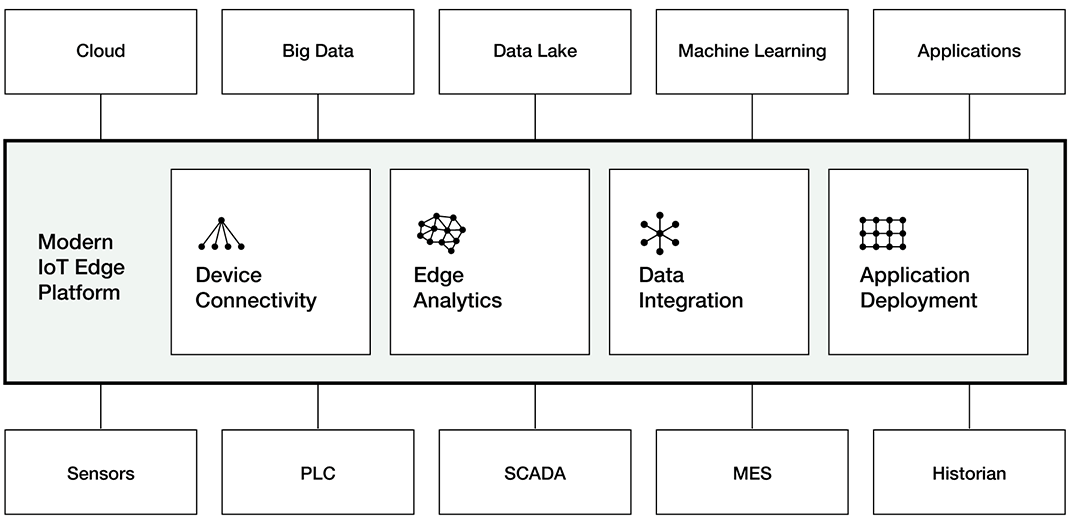

Litmus Edge Architecture

Litmus Edge is an all-in-one Industrial IoT platform designed to unify all OT data,

put that data intelligence to work to power applications, and scale seamlessly with centralized management.

The flexible Litmus Edge architecture

lays the foundation for complete, secure,

enterprise-scale data flow to enable any IIoT use case and improve operations at scale.

-

- OT Asset Connectivity

- Litmus Edge creates a unified OT data layer by connecting to every modern or legacy asset with ease - the critical first step for any successful Industrial IoT deployment. The platform handles the four key parts of OT asset connectivity – data collection, data normalization, data storage and data access.

-

- Data Intelligence

- Once all OT data has been collected and stored, Litmus Edge makes it easy to use the data intelligence to power any use case across the enterprise. Utilize ready KPIs, analytics and dashboards at the edge, or make the data available to any application for advanced analytics and data modeling.

-

- Centralized Management

- The only way to successfully scale Industrial IoT is with oversight and control over OT devices, data and applications. Litmus Edge Manager brings all data and management functions into one single point of control and easily scales to any number of assets for complete visibility.